The Production of PE Tarpaulin Sheet

Melt polyethylene particles to produce polyethylene film

Cut and stretch the film into polyethylene filament

The loom weaves the raw silk into a tear-resistant and stretch-resistant polyethylene bottom

Use pp rope to strengthen the strength of the edge and perform heat sealing

Cut or splice the tarpaulin to the corresponding size

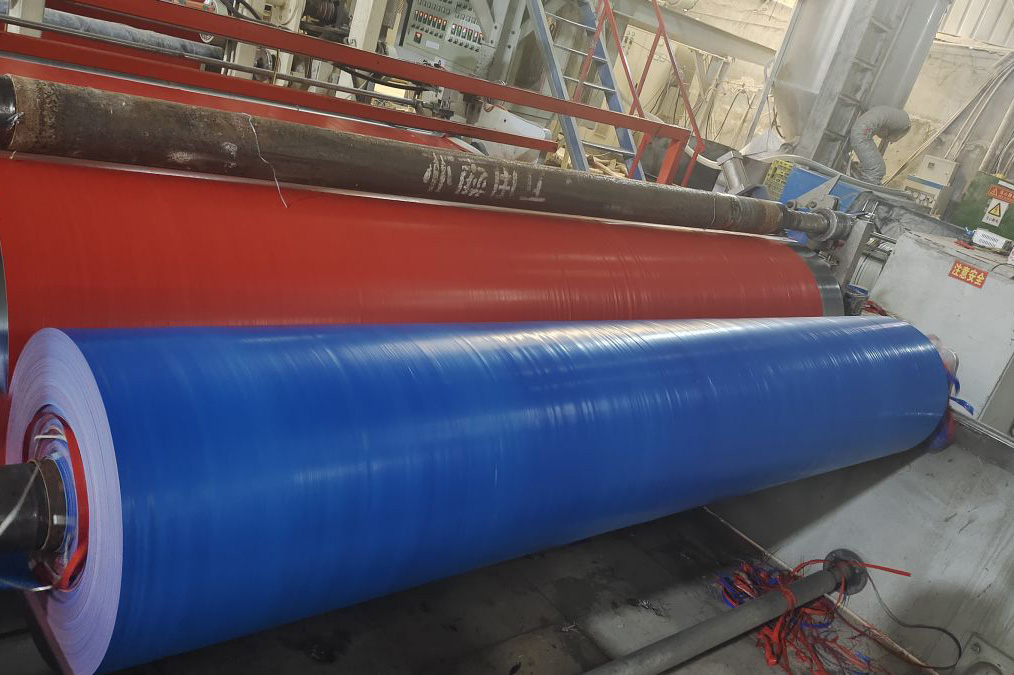

Use low-density polyethylene for color coating

Attach aluminum eyelets

Folding

Packaging

Shipping

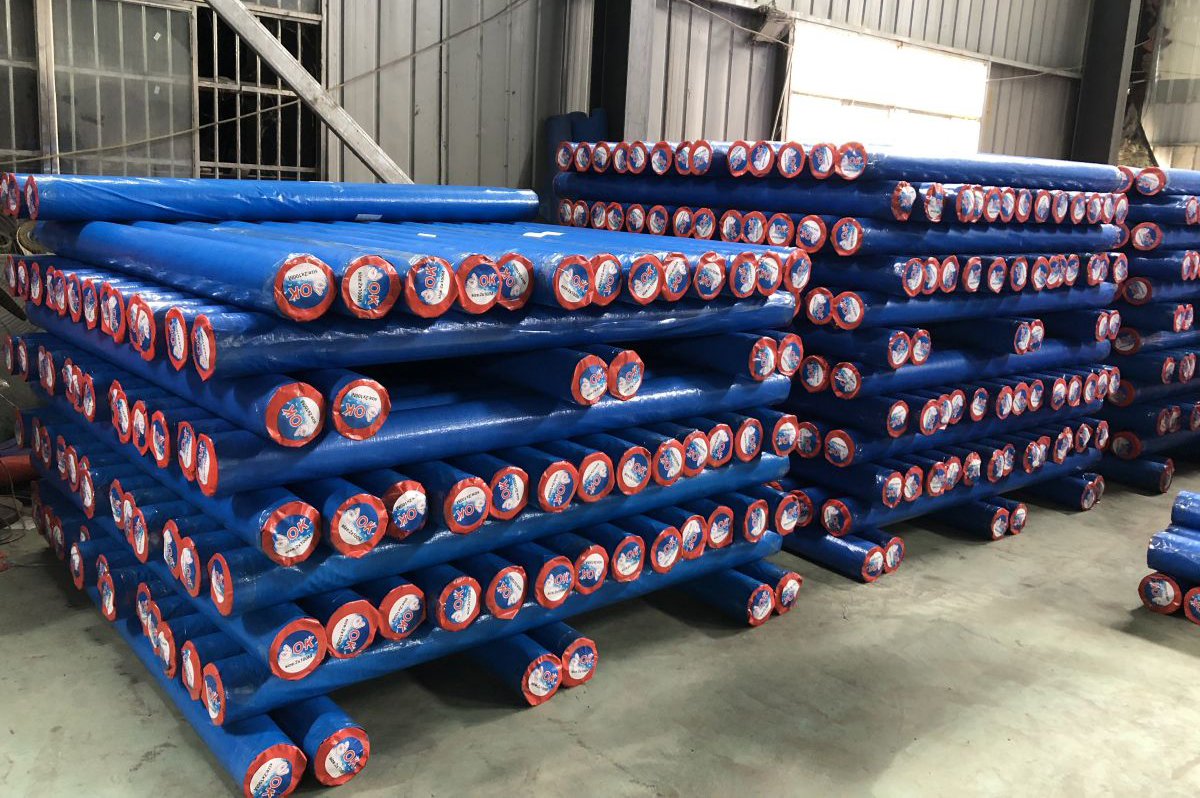

You can also buy PE tarpaulin roll. We will cut the coated tarpaulin into small rolls for you.

The production of PE tarpaulin sheets involves a complex process that results in a durable and versatile material used for various applications. PE tarpaulin sheets are made from polyethylene, a thermoplastic polymer known for its strength and flexibility. The production process begins with the selection of high-quality polyethylene resin, which is then melted and extruded into a thin sheet.

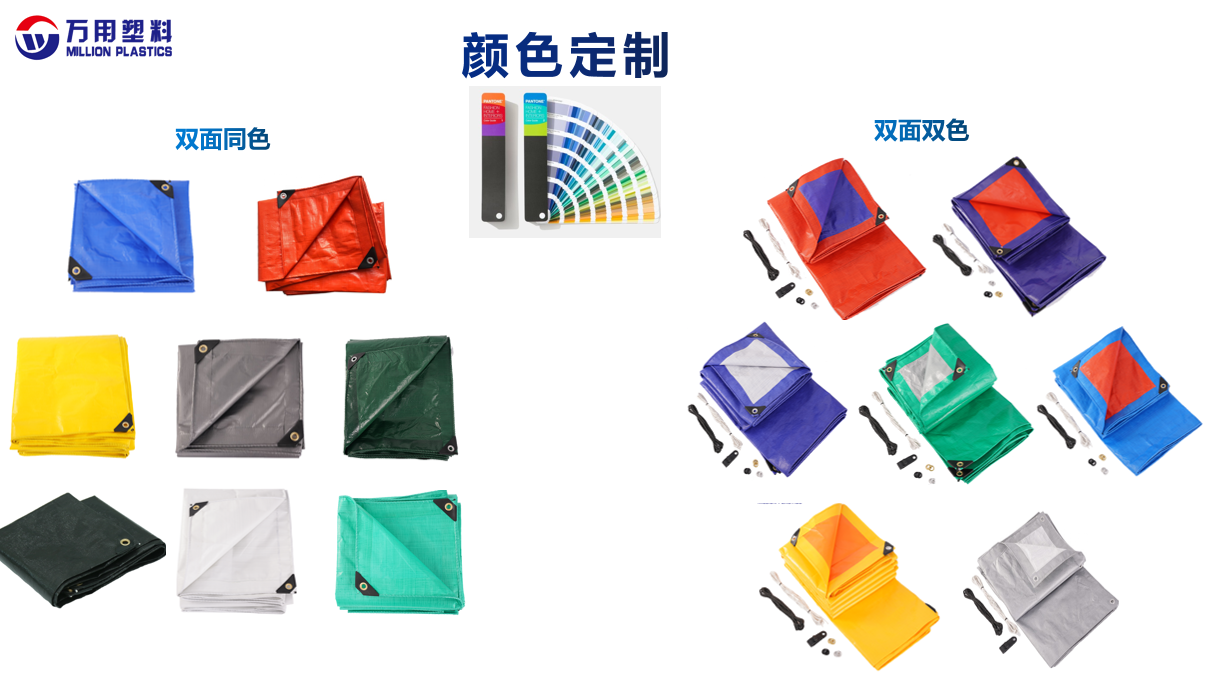

The first step in the production of PE tarpaulin sheets is the preparation of the raw materials. The polyethylene resin is carefully selected to ensure that it meets the required specifications for strength, durability, and UV resistance. Once the resin is obtained, it is melted and mixed with additives such as UV stabilizers and colorants to enhance its performance and appearance.

After the resin is prepared, it is extruded into a flat sheet using a specialized extrusion machine. The extrusion process involves forcing the molten resin through a die to create a continuous sheet of uniform thickness. The sheet is then cooled and solidified to form a flexible and durable material.

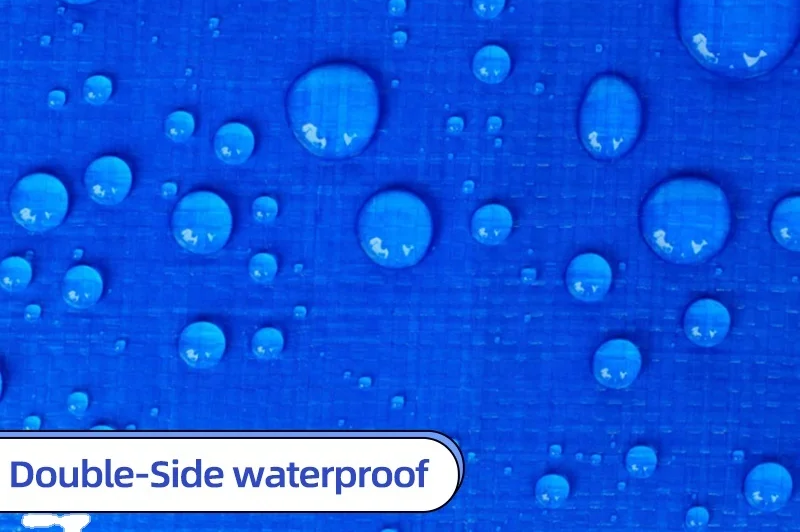

Once the PE tarpaulin sheet is formed, it undergoes further processing to enhance its properties. This may include treatments to improve its resistance to tearing, puncturing, and UV degradation. Additionally, the sheet may be coated with a protective layer to enhance its waterproofing and weather resistance.

The final step in the production process involves cutting and packaging the PE tarpaulin sheets for distribution. The sheets are cut to the desired size and shape, and then packaged for shipment to customers. The production of PE tarpaulin sheets requires precision and attention to detail to ensure that the final product meets the highest quality standards.

PE tarpaulin sheets are widely used in various industries, including construction, agriculture, transportation, and outdoor activities. Their versatility, durability, and weather resistance make them an ideal choice for covering and protecting goods, equipment, and surfaces from the elements.

In conclusion, the production of PE tarpaulin sheets involves a series of carefully controlled processes to create a durable and reliable material. From the selection of high-quality raw materials to the extrusion, processing, and packaging, each step is crucial in ensuring the quality and performance of the final product. PE tarpaulin sheets continue to be a popular choice for a wide range of applications due to their strength, flexibility, and protective properties.